Release time:2025-04-16

As mold processing is facing the pace of keeping up with new design changes and minimizing costs, the demand for five axis machining has become particularly important. The speed and accuracy of five axis machine tools provide a unique foundation for rapid response, high-speed cutting and excellent surface finish, thereby reducing the manual operation part.

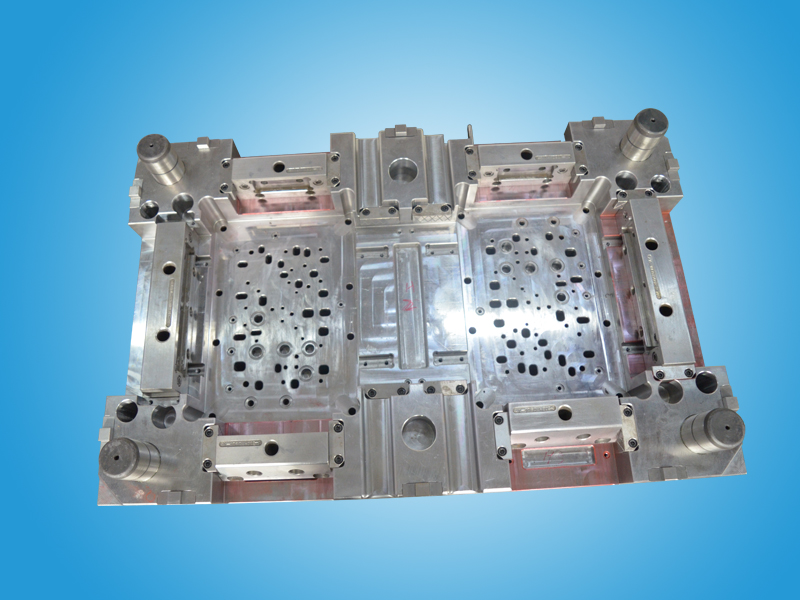

Mold is a necessary tool for mass production in modern manufacturing industry. The consumption industry of molds covers a wide range, including transportation machinery, industrial machinery, electric machinery and equipment, glass containers, packaging, building materials and equipment, medical treatment, etc. Since these products and equipment are mainly composed of widely used parts, components (assemblies) and components, almost every company manufacturing such equipment, products and components uses molds.

Five axis mold processing technology

With the development of mold parts manufacturing technology, five axis machining has brought greater productivity benefits to mold processing. Five axis mold processing technology can reduce the preparation stage by reducing the programming time, reduce the number of steps and procedures, and reduce the path of machining tools through the advantages of five axis machine tools.

The increasingly complex mold and medical parts design requires a new level of five axis machine tool performance. From rough machining to five axis mold processing with multi contour 3D geometry, five axis machine tools improve productivity with competitive processing capabilities, which are usually used for complex molds common in automotive, injection molding, packaging, medical and optical markets.

One of the main advantages of five axis die processing technology is that it improves the access of die components to part geometry. This can produce a more uniform and higher quality surface finish, thus providing: reduced tool costs, longer mold life, and fewer tools required for the project.

How can five axis machining benefit mold manufacturers?

People tend to think that five axis machining is to generate contour surfaces, and they are really good at this. However, there are many other benefits for mold manufacturers. An important problem is how to use traditional tools more effectively, such as ball end mills and new tools specially designed for five axis machining centers. For example:

Ball end mill: when the ball end mill feeds in a strict vertical direction, it actually drags the tool tip through the workpiece surface at a speed of zero rpm, which is hardly an effective cutting process. By tilting the tool relative to the workpiece surface, the effective cutting diameter increases, which can increase the metal removal rate by up to 40-50%, but still produce a better surface finish. In addition, the use of multi blade tools can prolong the tool life and reduce the cost of parts.

Barrel cutters: these cutters have contours, which can make wider cutting contact with the inclined workpiece surface, almost like super large ball end mills. These molds can provide equivalent or better surface finish through larger steps, thereby reducing the number of tool paths required to process 3D surfaces. Then, using the small radius tip of the mold, you can enter the narrow corner. Not only can more work be done with a single tool, but also continuous machined surfaces can be produced, significantly reducing mixing problems.

Shorter tools: three axis machining forces the use of longer tools to achieve some characteristics of cavity depth, which seriously affects the achievable machining speed. The tool holder can tilt away from the adjacent groove wall, and shorter tools can be used without the risk of collision, thus improving the processing efficiency and better surface finish.